Certification

according to

International standards

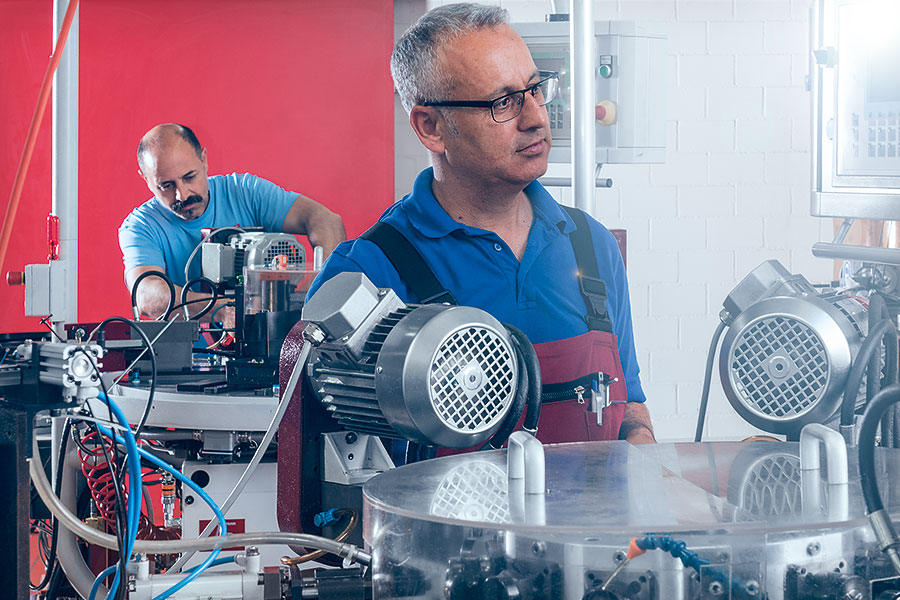

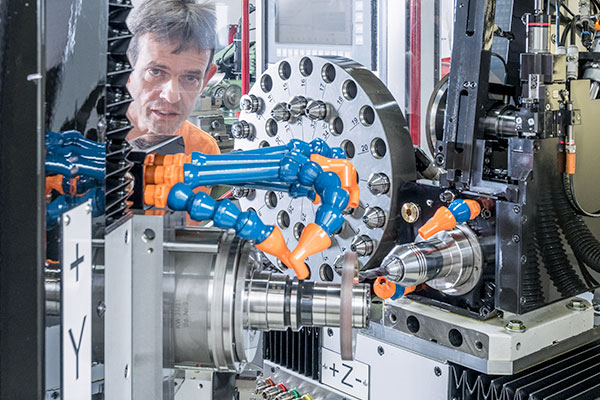

Our quality management system is regularly checked through recertification audits. To ensure that the measuring and testing equipment used records the right values, these are checked and calibrated at suitable intervals.

Initial sample inspection reports, material test documents, inspection certificates, hardness logs or individually requested documents are supplied with the products or archived at our company. Well-established QA measures play a major role in our supplying customers with top-quality products manufactured in accordance with the drawings.

Certifacation

Quality management through ISO 9001:2015, ISO 14001:2015 and ISO 13485:2016.

Under www.quality-service.ch you receive additional information.

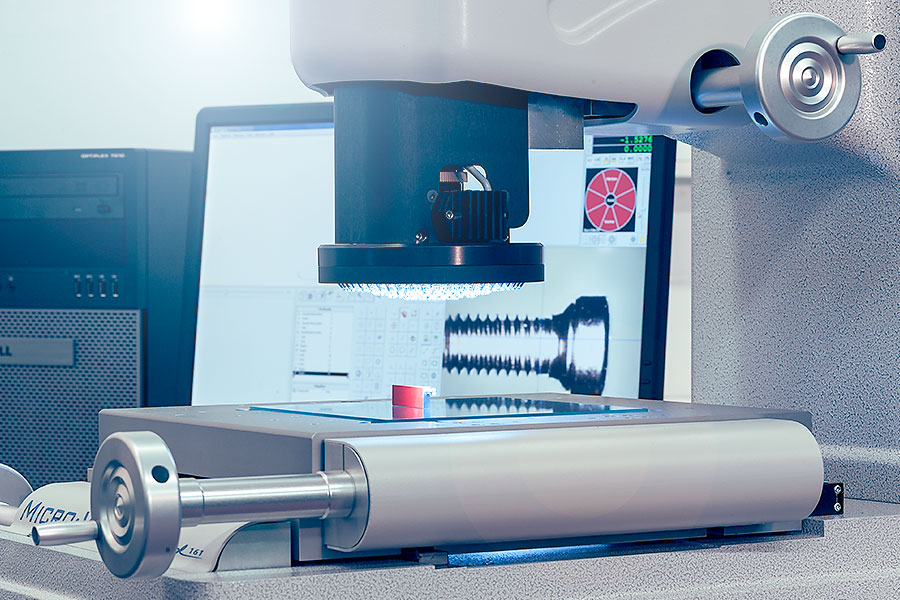

The latest measurement software generation can measure a large number of geometric features, for example an edge, a drilled hole, the height, radius or one of many other geometric elements, on a turned part and analyse the position, size and shape with a high-resolution CCD camera and image processing card.

Workpieces are reliably and efficiently measured contact-free using the most up-to-date technology. Measurement reports can be user-defined then printed, exported and easily tracked in all current formats.